From Concept to Finished Part

Engineered Plastics & Composites

About Us

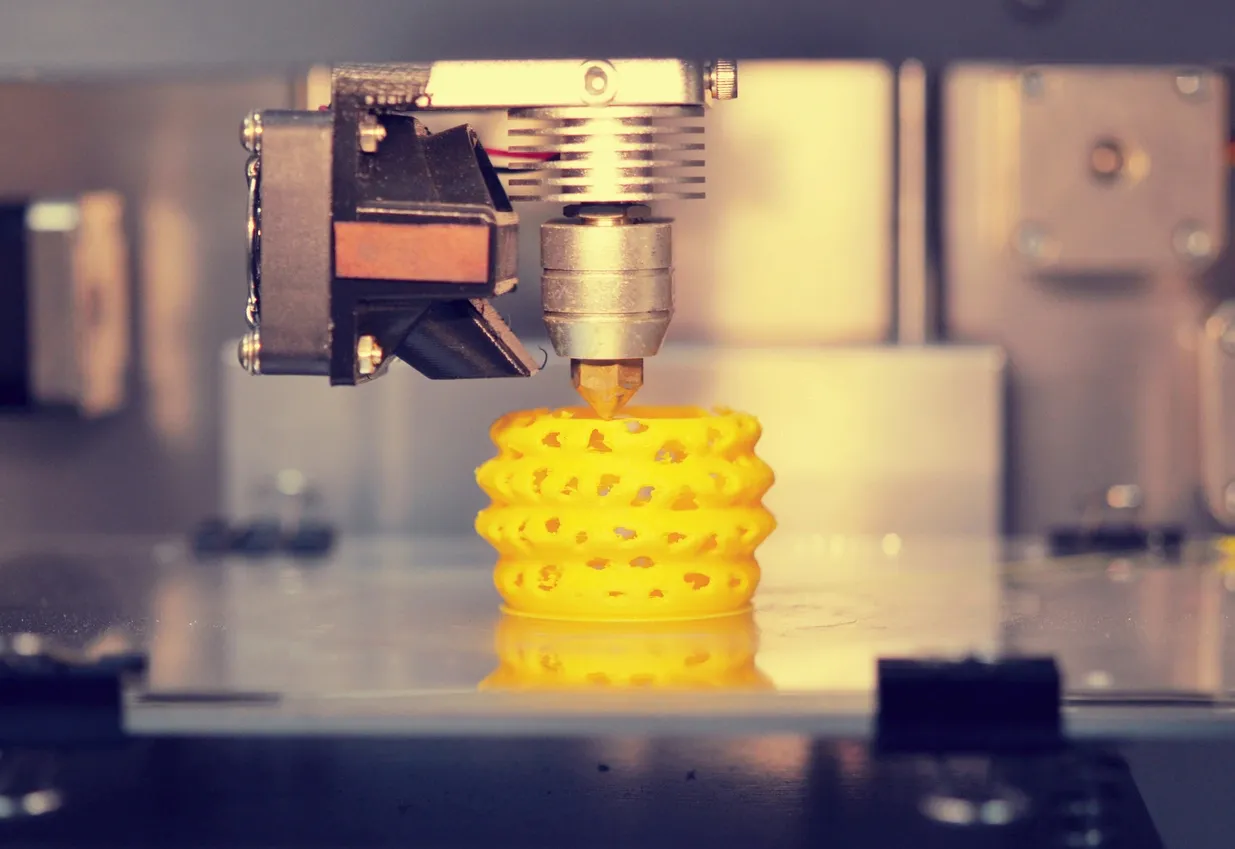

We are a dynamic company based in the heart of Lititz, PA, with over 30 years of expertise in 3D modeling and mechanical design engineering. We provide innovative 3D-printed FDM solutions to the local Lititz community and beyond. Today, our commitment to precision, efficiency, and quality is always present as we create custom fixturing, end-of-arm tooling, mounts, and anything we can imagine with our customers. Throughout their careers, our Engineers have honed their skills collaborating with industry leaders like BAE Systems, Collins Aerospace, Oakley, and Microsoft. We use this knowledge and skill set to provide cutting-edge solutions for diverse commercial, government, and industrial needs. As industry pioneers, we embrace challenges, addressing the most intricate requirements with groundbreaking solutions.

Services

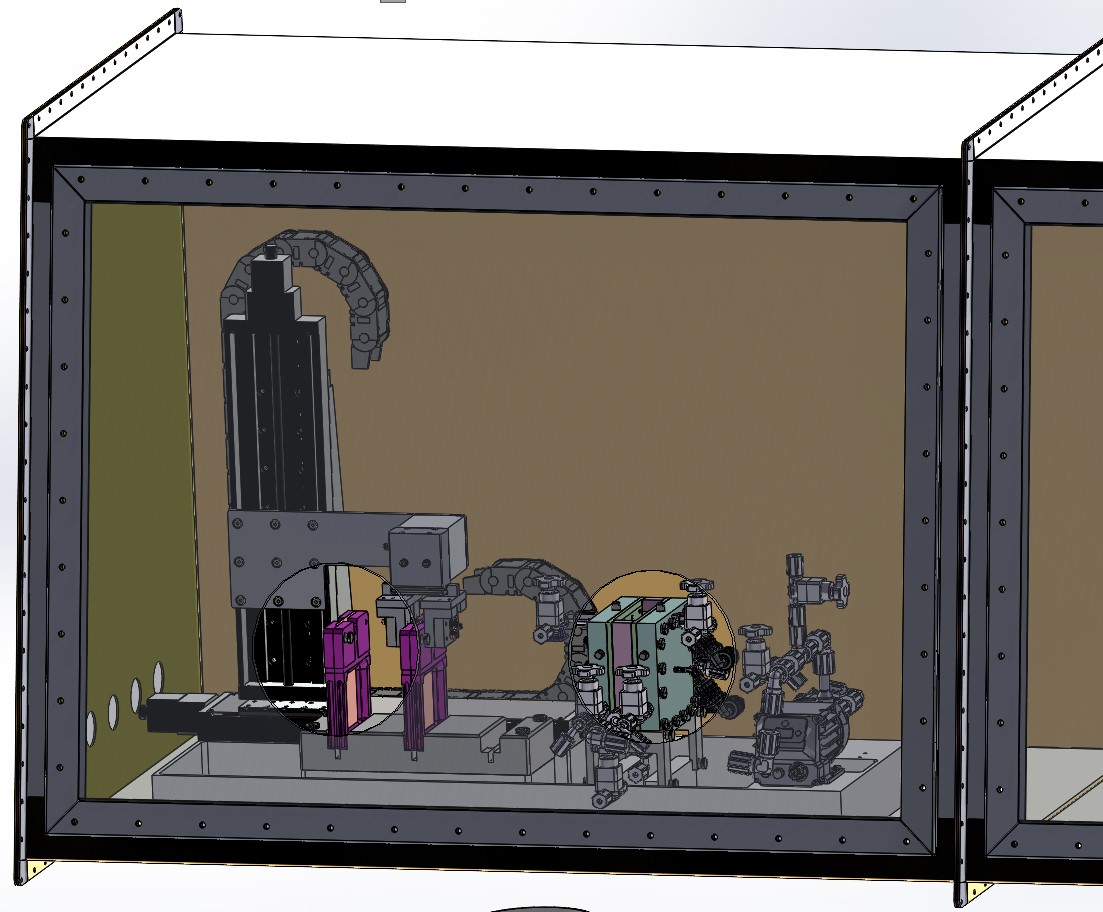

3D2Reality collaborates with your Engineering team to develop 3D models that meet your requirements, utilizing materials that provide you with the performance you need at the best price possible. You own the final product design. 3D2Reality provides CAD support, advice on modifications for manufacturability, material options, and of course your finished parts.

3D Design Review for Manufacturbility

We will review your design and recommend changes if warranted

Large Material Menu

From Simple ABS to High Temp Carbon Fiber Composites. Find the Right Material for your Application

From One-Off Engineering to Full Production

Our Machines are capable of producing one-off engineering prototypes, or high speed full production

3D Printing Materials

We offer a wide range of 3D printing filaments and resins to choose from. Our materials are tested for quality and compatibility with our printing systems, ensuring the best results for your projects.

The Right Material for Your Application:

- VICTREX AM™ 200 (LMPAEK™)

- Polycarbonate

- PEKK

- ULTEM™ 9085

- PEKK & Carbon-Fiber PEKK

- PEEK & Carbon-Fiber PEEK

- Aquasys® 120 and 180 Support

- Nylon (PA) and Nylon+CF

- Polycarbonate

- TPE

- TPU

- PVDF

- PVC

- HIPS

- ASA

- PPS

- PSU

- PPSU

- ABS

- PP

- PETx

- PPA

- PC-PBT

- PC-ASA

- PC-ABS

- PMMA (Acrylic)

- POM (Delrin)

…and more.

We offer a wide range of 3D printing filaments and resins to choose from. Our materials are tested for quality and compatibility with our printing systems, ensuring the best results for your projects.

Products

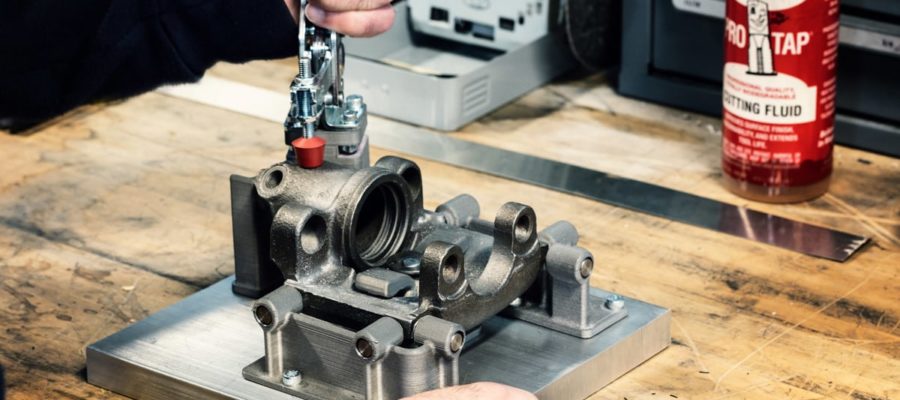

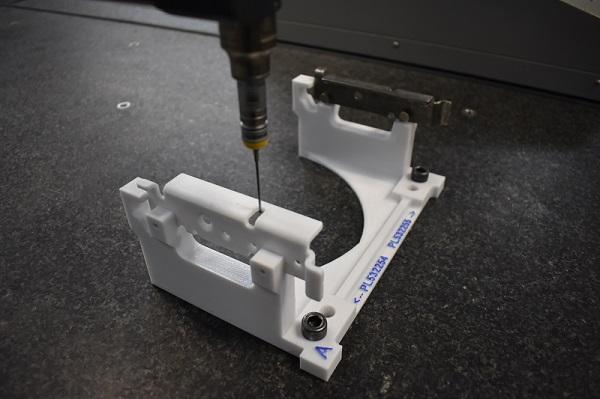

Manufacturing Process Fixturing:

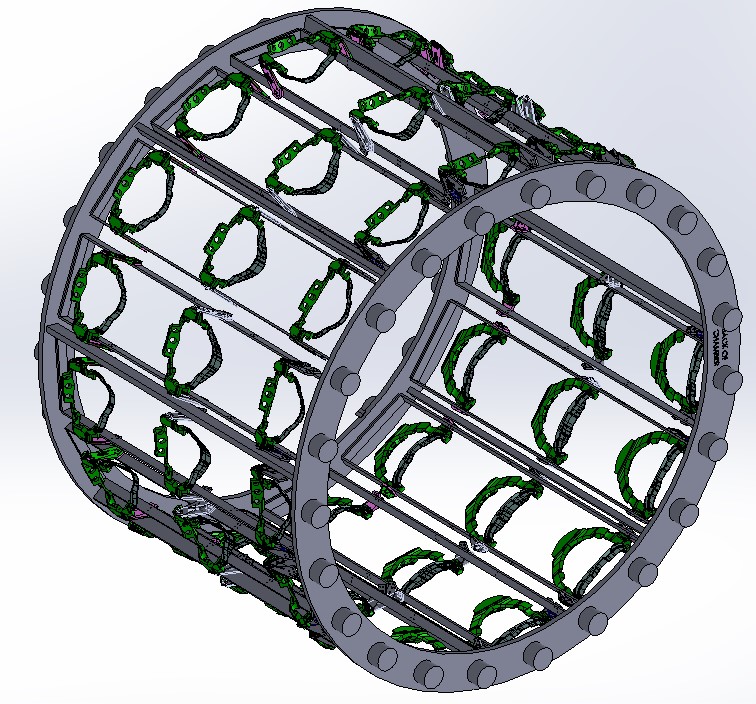

Unlock the full potential of 3D printing with custom process fixturing solutions. Designed in collaboration with your process Engineers and printed in-house with precision, these fixtures are crafted from high-performance plastics and composites. Fixtures that are not constrained by the limitations of conventional machining, allowing us to create configurations tailored to your unique manufacturing processes. Our team helps you select materials with meticulous care, considering factors such as chemical resistance, process temperature, wear resistance, and ESD requirements. When you choose us to manufacture your process fixturing, you’re opting for innovation, efficiency, and reliability.

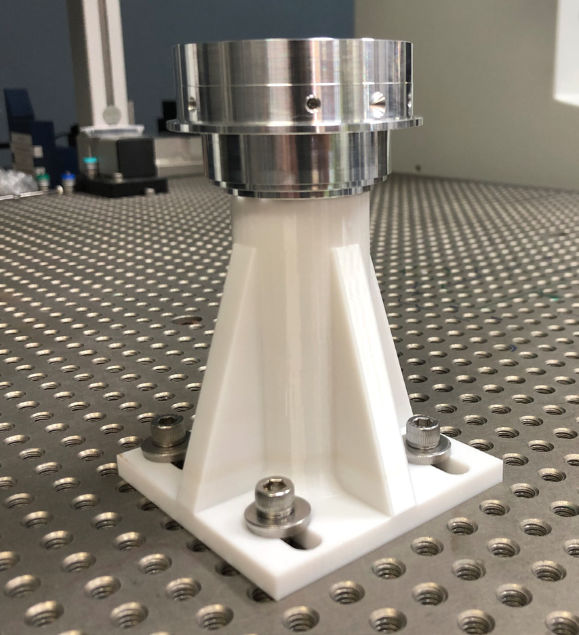

Vacuum Process Fixturing:

Experience a new level of efficiency with 3D printed vacuum process fixturing. We collaborate with your Process Engineers for precision and optimal performance. We utilize advanced plastics, including Sabic ULTEM™ AM9085F, known for its low off-gassing properties. This choice minimizes pump-down time and maximizes your process profitability. Notably, Sabic ULTEM™ AM9085F is one of the few plastics certified for use in spacecraft applications. When precision, cleanliness, and reliability are paramount, the vacuum process fixturing we produce rises to the occasion.

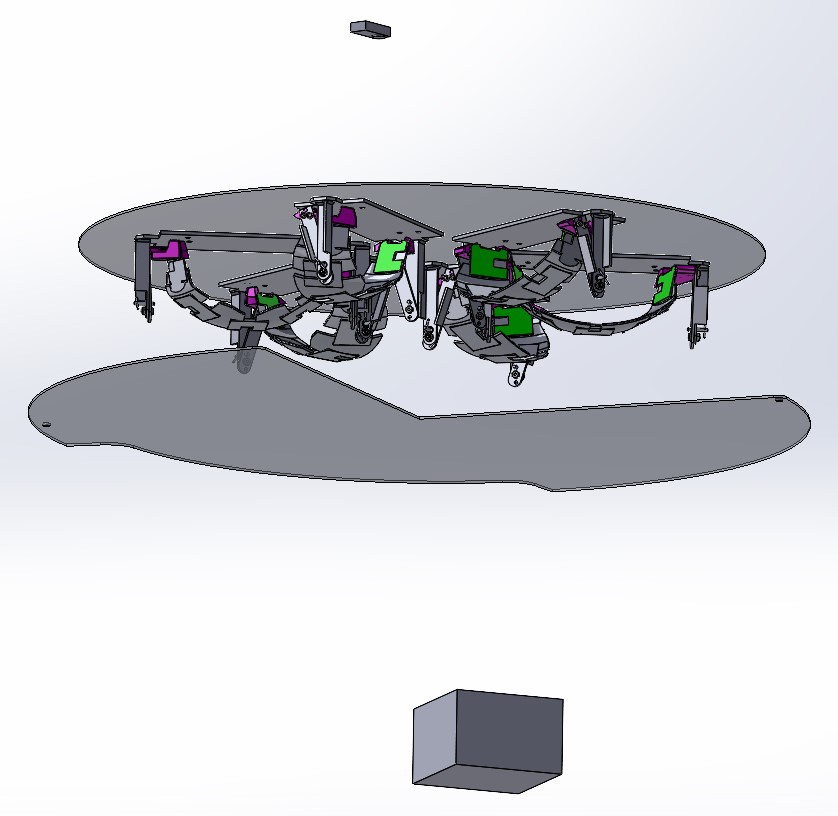

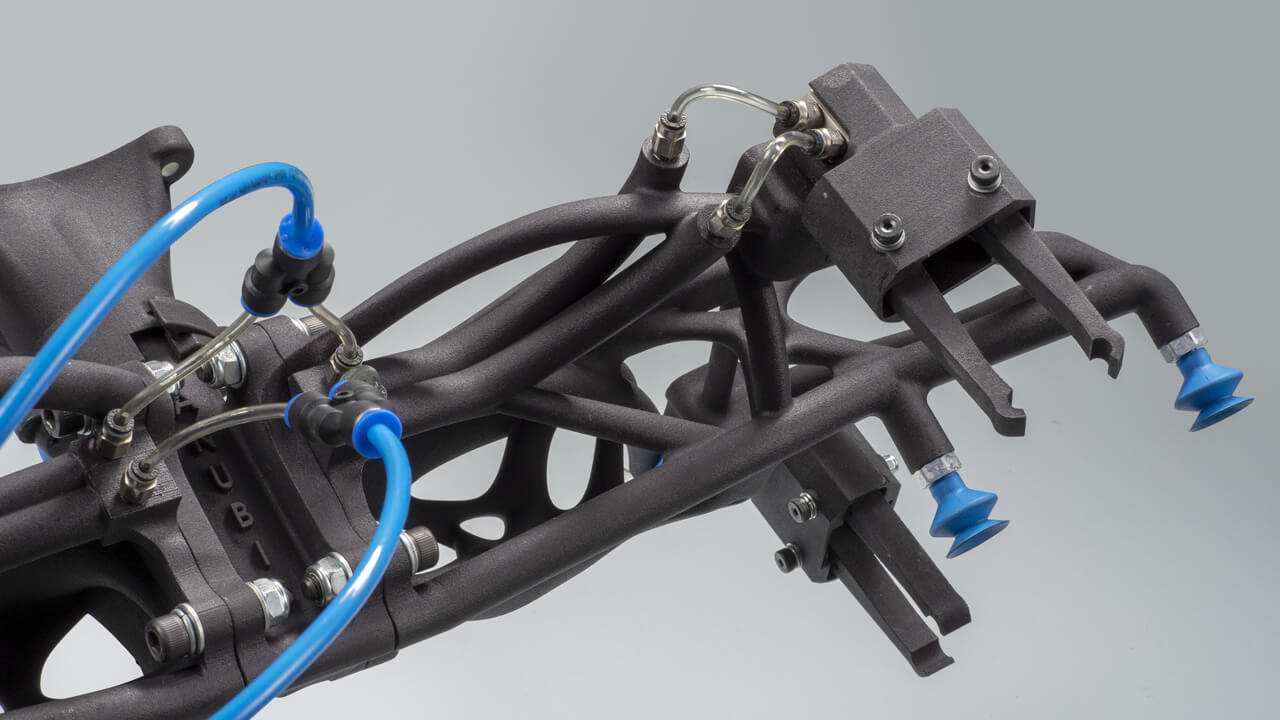

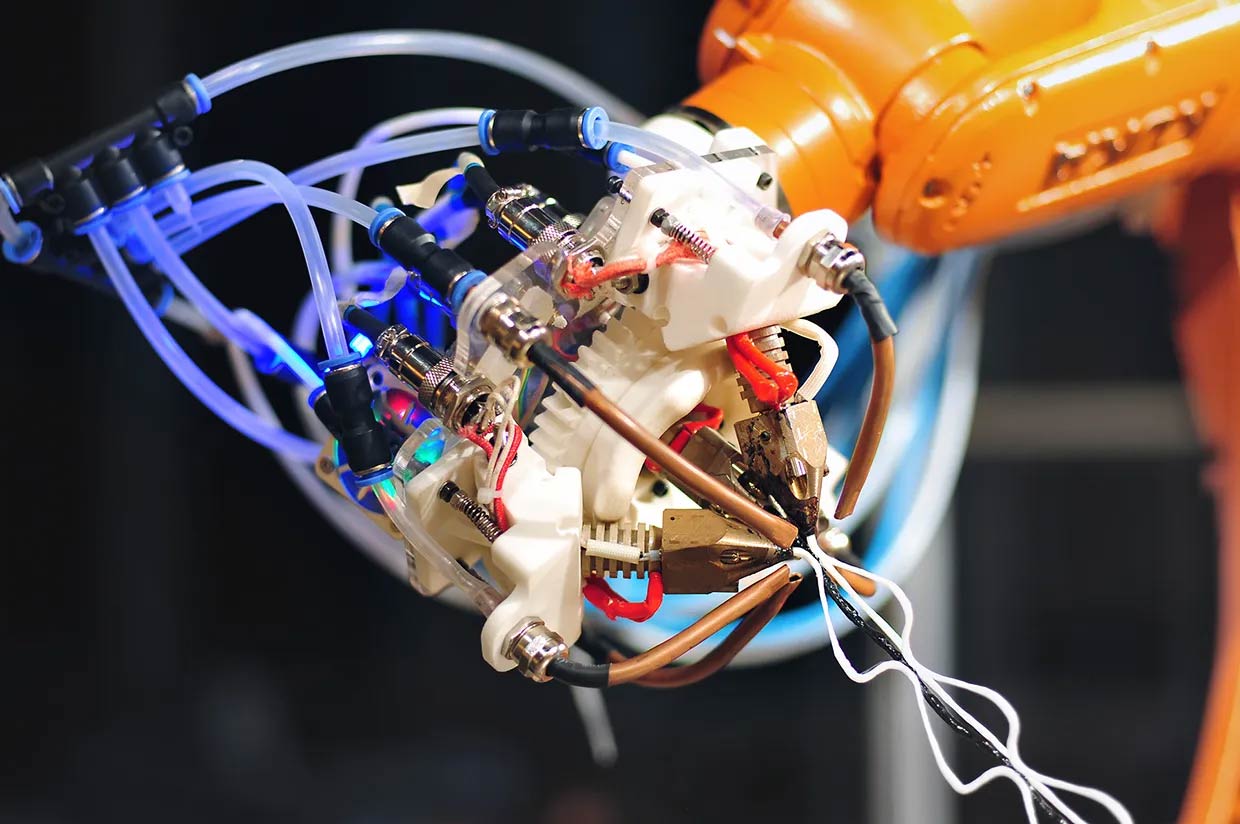

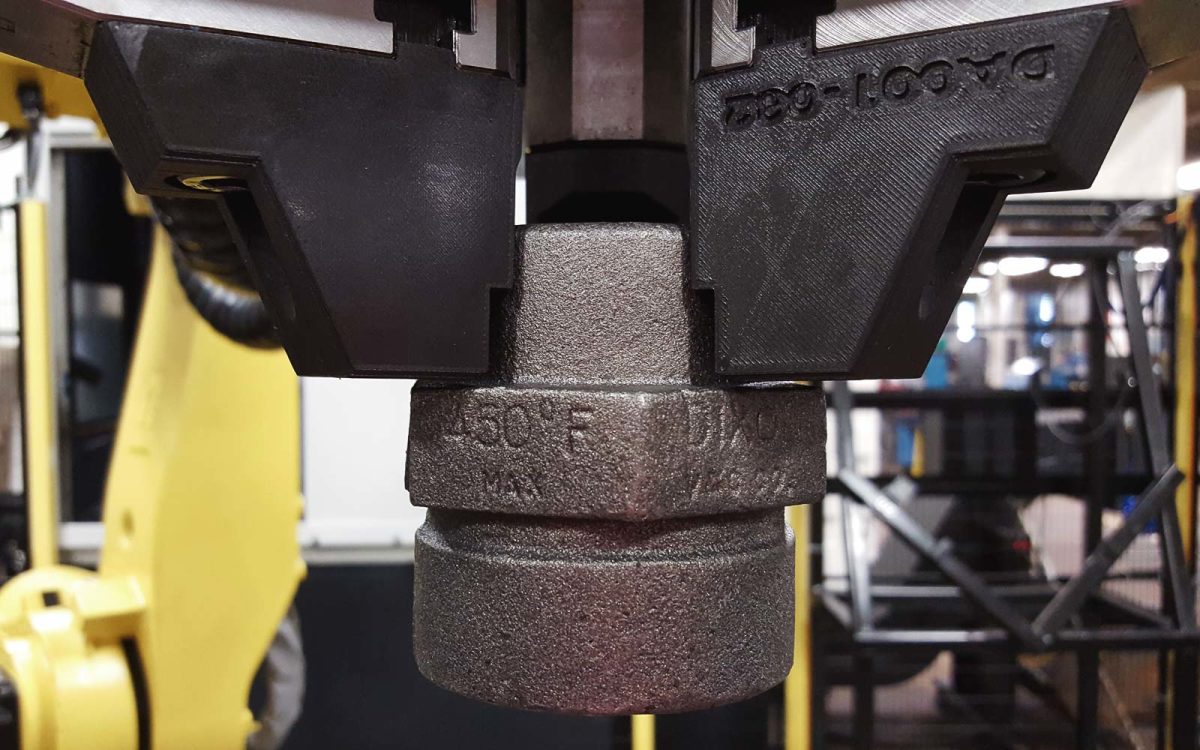

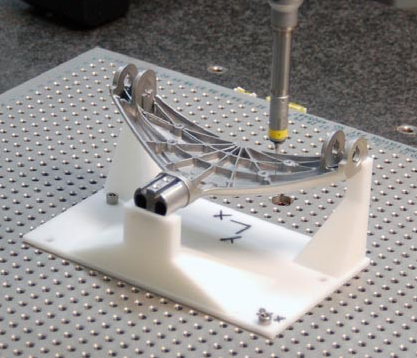

Component Handling Interfaces:

In the world of manufacturing, precision matters. The custom component handling interfaces we produce for you, which include pick-and-place end effectors and component handling grippers, are manufactured to the highest standards of quality. Crafted from durable plastics and composites, these components are built to endure the demands of your industry. We offer a wide selection of materials, including carbon fiber-reinforced ABS, ESD-safe ABS, sturdy PA-CF, heat-resistant and chemically resistant PEKK-A. These interfaces are engineered to seamlessly integrate into your workflow, ensuring precision and reliability with every use.

Equipment and Ergonomic Mounts:

Elevate your operations with precision equipment and ergonomic mounts. We work with your Engineers to design 3D printed components that meet or exceed your needs and expectations. From mounting equipment to enhancing ergonomics, products are designed to streamline your processes. We work with you to design a variety of solutions, including components to support 5S practices in your plant, equipment mounts for secure installations, and ergonomic hangers and mounts to improve operator comfort and efficiency. By choosing 3D2Reality to produce your mounts, you’re investing in a smoother, more efficient workflow.